Fashion print interview with | Busyman towel cotton digital printing heart.

- Share

- publisher

- Mr.Busy

- Issue Time

- Apr 24,2018

Summary

of course, the technology development of this year we have digital printing towel so fast, also depends on the front to lay the foundation in 67, my process of towels, towels, raw materials, process is relatively understanding, also have some of his own opinions, so to be able to make their own characteristics in the digital printing towel industry,

Q: fashion print editor-in-chief chunxia.

A: jiangsu non - lazy textiles co., LTD. Nantong coffee textile technology co., LTD.

Q: how do you do, Mr. Huang? Can you give us a brief introduction to jiangsu non-lazy company?

A: good, named not lazy BusyMan is hope we can keep A diligent and conscientious, is also A motivation of self.Company was founded in 2010, our products specialize in high-quality towels, since 2016, we focus on digital printing field with towel, after more than two years of hard work, very lucky in this respect, we have walked to the front at home, including our at the end of last year's new digital printing may be the first domestic double positioning towel.Of course, in the development of digital printing towel series, we have encountered a lot of sour and sweet.

We start from the production fabric to the printing, to the final cut, sew the finished product, the inspection, the packaging, the shipment, to the final product to the customer, not just the printing of this step.We are traditional towels, and now we add a digital printing line and production process.

Q: what is the share of digital printing in your entire product line?

A: these two years of digital printing series are our fast growing product series.At present, digital products can account for 40% to 50% of our company's orders.Because of the traditional towel products is more and more fierce competition, we at the same time of reduction of traditional product orders will be digital printing for the strong promotion of products, our company is also the core product of our company.

Many of our clients have done the comparison, we may not be the most preferential price, but for the quality of our products are recognized and printing effect, we are very confident in the digital printing industry.

A: we developed A double - sided digital print towel at the end of last year.At present, the towel market process of two-sided positioning is very difficult to achieve, and I understand that only our family is doing it.Many customers are also interested in the cost is much higher than the single print.

Q: how much will it cost?

A: about 25% more cost.

We have our own production process are all made of the process development of the process, just print parts adopt hope high-tech digital printing machine, our double-sided printing technology, is different from the shenyang flying boat double-sided printing technology, the speed of our relatively will be more quickly.

Q: at present, there are not many good companies in our country. Can you help us to analyze the pain points of towel digital printing?

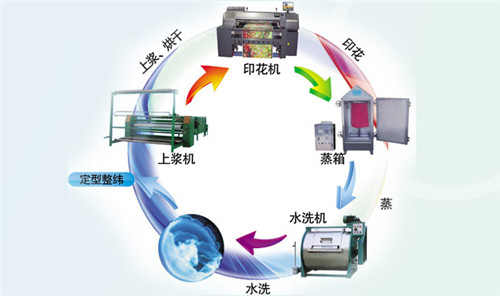

A: sizing is the first key pain points, because the towel is thicker, and suede, thicker than the general home textile fabrics should be 3-4 times, so the towel cannot one-time formation stenter, finalize the design, like home textile sizing, and particularly strong water imbibition and towel, so it's only walk in setting machine, drying and dry and suede is difficult to open the fluffy.Because when towel sizing elements over voltage and roller pressure, squeeze excess pulp, so that amount of sizing is more uniform, but this will lead to a crowded suede is rigid, it then the suede is blowing.Home textile fabric is thin, it does not pay attention to suede, it can be, I don't know how the sizing of the carpet, but is critical to our towel sizing process is also very difficult, this will involve a lot of our unique technology in sizing towel.

General home textile fabric is thin and flat, so sizing are generally able to achieve uniform requirements, but thicker towel fabrics, suede guidance is differ, sizing the requirements of the uniform is very high, if uneven, printed will have depth.Before we start to do digital printing towel, grain depth ratio is high, local color will be darker on the pulp, pulp on the local color will be lighter, less then it is easy to appear such problems, this is a batch of defective goods.

Followed by steaming, steaming in the towel industry is also very headache problem, clothing, home textile fabrics can even steaming, our company also has a batch of steamer, but even the batch of steaming out will find a lot of disadvantages, the key is stained with color problem.Through put even the batch of pipe spacing within the steamer in two to three times, and the pipe became thicker, can change the fabric, contact time, or not to make the fabric contact, for textile fabrics have been completely avoided, but on the towels will appear on the problem of color, because of towel fabric is thick, the drape of a it is not so vertical home textile and apparel fabrics, especially the brunet design part, this part of the towel ink quantity is big, and mostly float on the surface, the color is very easy to touch.

In addition, even the batch of steaming is without pressure steaming, and the permeability of towel after is color, so much ink is sprayed on the towel, requires the steaming process for ink and sizing of chemical reaction, make its ink disseminated through the loop.We use now steaming is steaming pot, a car is a car manual steaming pot, its production is much lower, but the effect of steaming it, bright color and permeability are higher than even the batch of steaming at least 10%.On our side and some even steaming equipment factory have discussed, they also acknowledge that even the batch of steaming color saturation and permeability is better than pressure steaming pot steamed out some shallower, and permeability is less.

After that, the water is washed, and the towels are washed with water and a single wash.The yield of the batch water is high, but it is not as good as a single wash to open the handle and suede, so we use a single wash.Single wash is used to ensure its color fastness according to different patterns.Because towels are in direct contact with skin directly products, its color fastness is higher, the activity of traditional printed towel color fastness standard is level 3 above is qualified, and our series products of digital printing fastness, perspiration fastness, washing fastness, washing fastness can reach level 4 or 5 basically, can meet the demand of the vast majority of customers.

In addition, digital printing has high requirements for fabrics.The fabric of our traditional towel, the manufacturing cost is lower, the effect of printing will be more obscure.Actually towel digital printing definition does not depend on the equipment and the precision of the nozzle, more often depends on the towel itself formation and the tightness of fabric, such as home textile fabrics, printed on 80 woven and printed on the 120 woven fabric must be effect, 120 woven must more careful.Our towel fabric is our own development process, belonging to a relatively flat and tight type.If you want to print a very good effect, it is required that the fabric is tightly knit and the suede is smooth.In order to achieve better results, first of all, to improve the weaving process, it is necessary to become a high-precision and high-density tissue to achieve the precise state of suede.Don't cut pile under the status of print is also vague, and not cut pile towel fabrics are less real in terms of penetration, cut pile on the one hand, will lead to better handle, also will be more rich full pattern.In addition to the fabric factor, of course, the equipment is also very important. Our equipment must be used with a large amount of ink and only enough ink to ensure its penetration is better.The truth of our towel and carpet is the same, it must reach better infiltration, the pattern that shows is true and full.

Q: how many machines do you have?

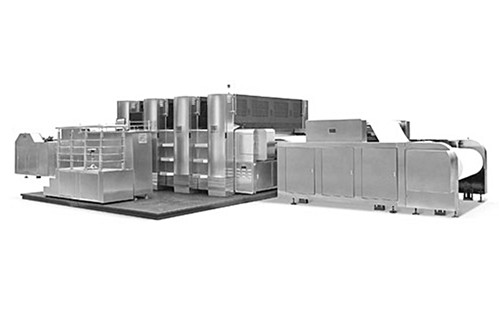

A: now we have A hope of high-tech industrial digital printing machine, also will again on 1 April JinKouJi Zimmer Austria, then we can output can reach 800 m day.

Q: how about the configuration of the equipment in gaoke?

A: we hope that the equipment of gaoko will be equipped with 32 stars with A width of 1.8 meters and an output of 140 meters and 150 meters per hour.

Q: how long has it been used for this device?

A: A little over A year ago, the equipment in February last year actually started production in March last year.

Q: how stable is the machine now?

A: the stability is ok, but sometimes the software is error-prone.But I think their service is still very good, very cooperative.If there is any problem, we hope that the high school can solve the problem in time. If the problem is bigger, they can come to our site very quickly.

Q: is it in place within 24 hours?

A: for some big problems, they can arrive within 24 hours;If it is a small problem, we hope that the high-tech will be solved by remote, video and telephone.If we can't solve the problem, they'll send someone over immediately.We are willing to work together to solve the problem, and the best thing is to do well.

Q: why did you choose Zimmer for the next machine?

A: after all, Zimmer has been studying carpets and towels for decades.I feel they are more skilled in craft and industry than equipment.

Q: installed in April?

A: yes.Many of the orders we receive now are especially suitable for digital printing.First of all, these orders are mostly short and fast orders, and one order is about a few hundred meters.Secondly, the customer demands that the delivery date is fast. We are professional towels, all the fabrics are their own, and are fixed several specifications, so we have an advantage in the delivery time.

A: digital printing towel is A trend, but the added value of it will be A lot less than home textile clothing, because towels belongs to daily consumption goods, unit price is lower, rarely more than 100 yuan, but the clothes is different, the cost is controlled in 100 yuan of clothes can sell for hundreds and even thousands of yuan, added value is much better than the towel.

Let's assume that our digital printed towel daily output is 8000 meters, and the annual output is 360 days. It can produce 2.88 million meters in a year, and the total output value will reach 2.5 billion.What is the concept of 2.5 billion?The current market order quantity is not yet available, so 360 days may only be open to 150 days, the capacity of one day could be 4000 meters.We need to open the market, because in the industry know that digital printing towel or less, the market acceptance of it may be less, so the current market demand is not so big, we need to go to a little bit of development and open the market.

The cost of digital printing is now high, more than twice the cost of traditional active printing, and it is difficult for many customers to accept it and it is difficult to market it.So where does digital print go?Where is its market?It must be that the pattern is very complicated, it must be the star, the team, the concert, the concert, the animation and other customized things are more popular.There is also an urgent delivery time, a smaller quantity of orders.

In terms of pattern, such as some traditional printing can't print the pattern we can print, just as a cost doubled, but the price have no double, such as the original do 10 yuan a towel price 50 yuan, I now do 20 yuan a is less than 100 yuan.Now most of us do export, mainly exported to Japan, the Japanese towel price is higher, such as this one square in Japan will be selling to 50, 60 yuan, 5 yuan in our country there are people who want to think about it.

Q: how much is the market per year in Japan?

A: the Japanese market is relatively large, with 5 to 10 square towels per person in Japan, because the Japanese don't use paper towels.Japanese people are afraid of heat, wipe sweat to get a square towel, clean also need to get a square towel, then everyday will wash or throw away.

Q: do they like this kind of flowers?

A: no, there are many kinds of Japanese towels. There are different materials. There are different patterns. There are different crafts. Digital printing is only A little more beautiful.Japan's advanced digital printing technology earlier than we want to, but now China has to catch up with them, even more than they, just price is high in Japan, this leads to more and more Japanese customers trend in our production in China.

Q: what is the cost control in our country?

A: our current cost is between 4 yuan and 8 yuan, and all the costs are included.

Q: you look so young and promising. Can you tell me something about your entrepreneurial journey?

A: I'm A sophomore year out of school and starting to open company, I studied xuzhou normal university (now jiangsu normal university) math major, I have come out and improper teacher, learned math study, feel no meaning, so he was desperate to come out, itself also prefer to do business, think you can rushes out A slice of heaven and earth, and so it came out.Of course, it didn't go so well. I came out of school in 2008. I also worked as a driver when I came out.In 2010 while on a foreign trade company investment is lower, the registered a foreign trade company in February 2010, or more, of course, parents support my business, such as the registered alibaba to 19800 yuan is my parents' support, but the real key is to rely on our own efforts.

At that time we are foreign trade company main towel industry, because feel towel products is simpler, good introductory, looking for one or two people have been doing, jacquard towels was then, ordinary printing, embroidery, or plain.In 2013 we began to study the digital printing, digital printing equipment, 2 years ago but because the equipment is not mature so to return, there are also many among slowly running-in process is not successful.The year before last, I felt that the digital print towel was about to enter a big market, and I began to delve into it, and last year I had the first hope for the high-tech industrial digital printing machine.

Q: did you make a profit when you started your business?

A: there was no profit in that year, but there was no expense. Just one employee, with low salary, made several orders and made A total of 100,000 and 200,000 sales.

When I started my business, I worked very hard. I slept in the office at night and worked from 7 am to 12 PM.At that time FOB does not understand, export trade does not understand, the professional knowledge on towel does not understand, alibaba website also does not operate, so from morning sit to evening study.If you don't know how to do a towel, you can take two bottles of wine and go to someone's factory to ask your teacher for advice, and talk to your boss.In the evening, you can learn more knowledge. As long as you want to learn something that you can't learn, you will gradually accumulate your own experience.

, of course, the technology development of this year we have digital printing towel so fast, also depends on the front to lay the foundation in 67, my process of towels, towels, raw materials, process is relatively understanding, also have some of his own opinions, so to be able to make their own characteristics in the digital printing towel industry, in fact, I think I talk about the product more interested in more than about their good at, such as our printed towels and clear, color and rich, and full color, ha ha.

The above is Fashion print interview with | Busyman towel cotton digital printing heart..editor introduced to everyone .If you want to know more about digital printing towel related content , please pay attention to Jiangsu Busyman Textile Co., Ltd.http://www.towelkingdom.com/